The world of porous materials has witnessed a quiet revolution over the past two decades, one that has unfolded not in industrial laboratories but in the precise realm of molecular design. Metal-organic frameworks, or MOFs as they're commonly known, represent more than just another class of materials—they embody a fundamental shift in how scientists approach the creation of functional porous structures. These crystalline networks, composed of metal ions or clusters connected by organic linkers, have rewritten the rules of material design by offering unprecedented control at the molecular level.

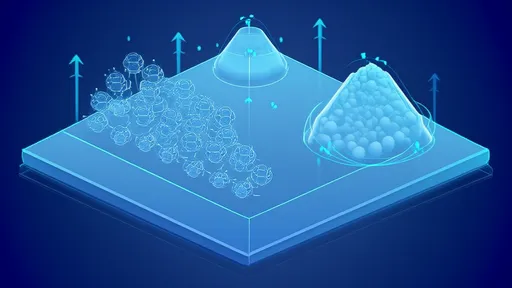

What sets MOFs apart from traditional porous materials like zeolites or activated carbon isn't merely their higher surface areas—though some MOFs boast enough internal surface that a single gram could cover an entire football field if unfolded. The true paradigm shift lies in their designer nature. Unlike naturally occurring porous materials that must be adapted for applications, MOFs are built from the ground up with specific purposes in mind. This bottom-up approach allows researchers to fine-tune pore sizes with angstrom-level precision, decorate internal surfaces with functional groups, and even create dynamic structures that respond to external stimuli.

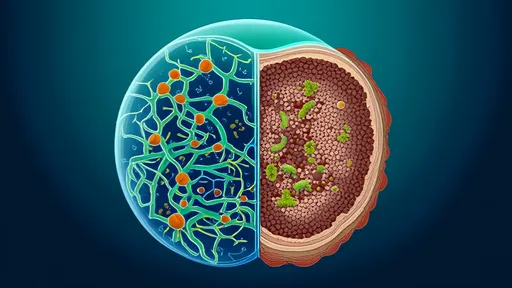

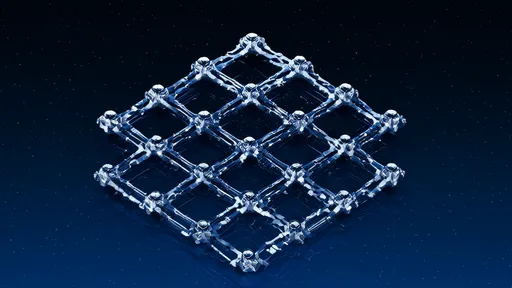

The architectural flexibility of MOFs stems from their modular construction. Imagine molecular Tinkertoys where metal nodes act as junctions and organic ligands serve as connecting rods. This building-block approach has yielded an astonishing chemical diversity—over 100,000 distinct MOF structures have been reported to date, with potential variations numbering in the millions. Such structural tunability enables properties that would be impossible in conventional materials, such as pores that selectively expand when exposed to certain gases or channels that change shape upon light exposure.

One particularly promising application area for MOFs lies in gas storage and separation. The natural gas industry has taken keen interest in MOFs that can store methane at much lower pressures than conventional compressed natural gas tanks. Similarly, researchers have developed MOFs capable of separating ethylene from ethane—a notoriously energy-intensive industrial process—with far greater efficiency than traditional cryogenic distillation. These advances could dramatically reduce energy consumption in petrochemical processing while improving safety.

Environmental applications have also benefited tremendously from MOF technology. Certain water-stable MOFs can capture carbon dioxide from flue gases with exceptional selectivity, while others show promise for removing toxic heavy metals from water supplies. The precision of MOF pores allows them to discriminate between molecules of nearly identical size—a capability that could revolutionize air purification systems and water treatment plants alike. Some MOFs even break down chemical warfare agents into harmless compounds, demonstrating their potential for military and civilian protection.

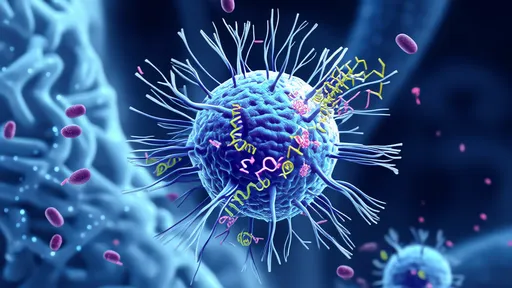

In the biomedical realm, MOFs are opening new frontiers in drug delivery and medical imaging. Their high porosity enables drug loadings far exceeding traditional carriers, while surface modifications can target specific tissues or organs. Researchers have engineered pH-sensitive MOFs that remain stable in the bloodstream but release their cargo upon encountering the acidic environment of tumors. Other groups have developed MOF-based contrast agents that provide superior resolution in magnetic resonance imaging while carrying therapeutic payloads—a true theranostic approach.

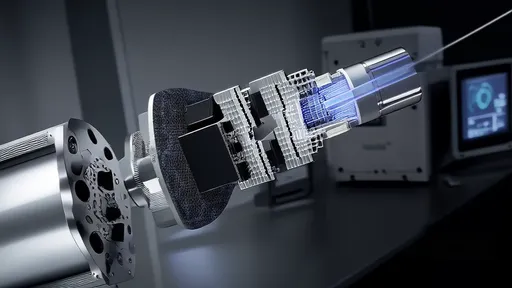

The electronics industry has begun exploring MOFs for next-generation devices. Their unique combination of porosity and electrical conductivity in some variants makes them ideal candidates for supercapacitors and batteries. Certain MOFs demonstrate exceptional performance in storing lithium ions, suggesting they could enable safer, higher-capacity batteries. Others exhibit remarkable dielectric properties or proton conductivity, pointing toward applications in flexible electronics and fuel cells. The ability to precisely arrange molecular components within MOFs may eventually lead to molecular-scale electronic circuits.

Despite these exciting developments, challenges remain in translating MOF technology from laboratory curiosities to commercial products. Scale-up synthesis often proves difficult, as the crystalline perfection achieved in small batches doesn't always translate to industrial production. Many MOFs also suffer from stability issues when exposed to moisture or harsh chemical environments—a significant hurdle for real-world applications. Researchers are addressing these limitations through innovative approaches like hybrid MOF-composites and surface coatings that enhance robustness without sacrificing functionality.

Looking ahead, the field continues to evolve in fascinating directions. Machine learning is accelerating MOF discovery by predicting properties of hypothetical structures before synthesis. Researchers are developing "smart" MOFs that incorporate multiple functions—perhaps storing hydrogen while monitoring tank integrity through built-in sensors. There's even work on MOF-based artificial photosynthesis systems that could convert carbon dioxide into fuels using sunlight. As synthetic techniques improve and fundamental understanding deepens, MOFs may well become as ubiquitous as plastics in modern technology.

The story of MOFs serves as a powerful reminder that materials innovation often follows conceptual breakthroughs rather than incremental improvements. By treating porosity not as an inherent material property but as a design feature to be precisely controlled, MOF researchers have created an entirely new toolbox for solving engineering challenges. From environmental remediation to energy storage, from medical therapeutics to advanced electronics, these molecular scaffolds are proving that sometimes the most powerful solutions come not from nature's ready-made materials, but from our ability to envision and construct molecular worlds from the ground up.

As with any transformative technology, the full impact of MOFs may take decades to realize. But already, their influence extends beyond practical applications—they've fundamentally altered how chemists and materials scientists think about designing functional materials. In an era demanding sustainable solutions to global challenges, MOFs offer something invaluable: a molecular canvas where scientific imagination can meet engineering precision to create materials tailored for the problems of our time.

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025