Metal Nanocatalytic Surface Reconstruction: Atomic-Layer Dynamics in Catalytic Reactions

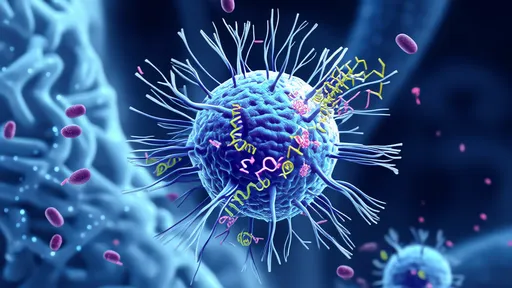

The field of nanocatalysis has witnessed a paradigm shift in recent years with the growing recognition of dynamic surface reconstruction in metal nanoparticles during catalytic processes. Unlike traditional views that treated catalysts as static entities, cutting-edge research now reveals that catalytic surfaces undergo continuous atomic-scale rearrangements under reaction conditions. These reconstructions, far from being mere structural curiosities, often dictate the activity, selectivity, and stability of catalytic systems.

High-resolution microscopy and advanced spectroscopic techniques have allowed scientists to observe these phenomena in real-time. What emerges is a picture of astonishing complexity - metal surfaces breathe, ripple, and reconfigure themselves at the atomic level in response to chemical environments. This dynamic behavior challenges conventional wisdom about structure-activity relationships in catalysis and opens new avenues for designing more efficient catalytic materials.

The Dance of Atoms Under Reaction Conditions

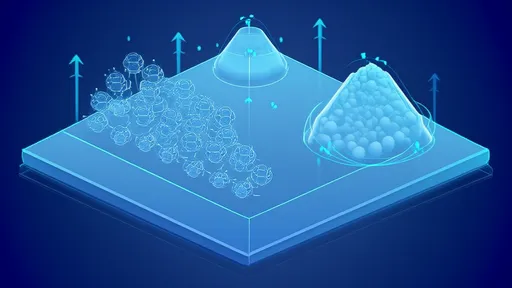

At the heart of surface reconstruction lies the delicate balance between thermodynamic driving forces and kinetic constraints. When metal nanoparticles are exposed to reactive gases or elevated temperatures, their surface atoms frequently abandon their equilibrium positions. This occurs because the energy landscape of surface atoms changes dramatically when interacting with adsorbates. The result is a constantly evolving interface where the catalyst adapts to its chemical environment.

Recent studies on platinum-group metals have shown particularly striking examples of this behavior. Under oxidizing conditions, certain crystal facets may reconstruct to form oxide-like structures that are more stable in the presence of oxygen. Conversely, in reducing environments, these same surfaces might revert to metallic configurations or adopt entirely new arrangements that optimize binding with hydrogen or other reductants.

Implications for Catalytic Performance

The practical consequences of surface reconstruction are profound. Catalysts that appear identical in pre-reaction characterization may develop dramatically different active surfaces during operation. This explains why seemingly small changes in pretreatment protocols or reaction conditions can lead to large variations in catalytic performance. The dynamic nature of active sites means that traditional approaches to catalyst optimization, which often focus on initial structures, may miss the most important aspects of catalytic behavior.

Perhaps most intriguing is the growing evidence that the most active catalytic states are often metastable configurations that exist only under reaction conditions. These transient structures cannot be observed in post-reaction characterization, creating what researchers have termed the "materials gap" in catalysis - the disconnect between the materials we can characterize and those actually performing catalysis.

Experimental Breakthroughs and Challenges

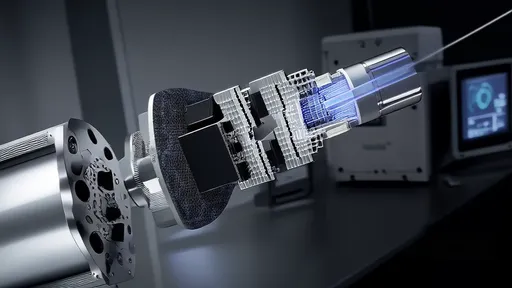

Advanced characterization tools have been crucial in uncovering these phenomena. Environmental transmission electron microscopy (ETEM) allows direct observation of surface dynamics at near-atomic resolution under realistic pressure and temperature conditions. Similarly, synchrotron-based X-ray techniques provide element-specific information about structural changes during catalysis. These methods have revealed phenomena such as surface roughening, facet reconstruction, and even complete morphological transformations of nanoparticles during reactions.

However, significant challenges remain in connecting these observations to catalytic performance. The timescales of surface reconstruction often differ from those of the catalytic cycle, making it difficult to establish clear structure-activity relationships. Moreover, the presence of multiple concurrent reconstruction pathways complicates the interpretation of experimental data. Researchers are now developing multimodal approaches that combine several characterization methods with computational modeling to overcome these limitations.

Computational Insights into Dynamic Surfaces

Theoretical approaches have played a crucial role in understanding surface reconstruction. Ab initio molecular dynamics simulations can now track the movements of hundreds of atoms over timescales relevant to catalytic processes. These simulations reveal that reconstruction is often initiated by the formation of local defects or the adsorption of key reactant molecules. Once started, the reconstruction can propagate across the surface through concerted atomic movements.

Machine learning potentials are accelerating progress in this area by enabling longer timescale simulations with quantum mechanical accuracy. These methods have predicted several reconstruction patterns that were later confirmed experimentally, validating the computational approach. Importantly, simulations suggest that certain reconstruction patterns may be universal across different metals when normalized by factors such as surface energy and atomic radius.

Designing Catalysts with Dynamic Stability

The recognition of surface reconstruction has led to new strategies in catalyst design. Rather than trying to prevent reconstruction - often an impossible task - researchers are learning to work with it. One promising approach involves creating materials that can cycle between different reconstructed states during the catalytic process, with each state optimized for a particular step in the reaction mechanism.

Another strategy focuses on stabilizing beneficial reconstructions through careful control of nanoparticle composition and support interactions. Core-shell structures, for instance, can be designed to induce specific strain patterns in the active surface layer, favoring desired reconstruction pathways. Similarly, oxide supports can be chosen to electronically modify metal nanoparticles in ways that stabilize catalytically active surface configurations.

Future Directions and Applications

As understanding of surface reconstruction grows, so does its potential impact across various catalytic applications. In energy conversion technologies such as fuel cells and electrolyzers, controlled surface reconstruction could lead to more durable and active electrocatalysts. For chemical manufacturing, dynamic catalysts might enable more selective transformations with reduced energy requirements. Even in environmental catalysis, tailored reconstruction behavior could improve the abatement of pollutants under fluctuating conditions.

The next frontier in this field involves moving from observation to control. Researchers are developing methods to actively steer reconstruction processes using external stimuli such as light, electric fields, or periodic changes in reaction conditions. This level of control could ultimately lead to catalysts that adapt their surfaces in real-time to maintain optimal performance as reaction conditions change - a concept sometimes called "adaptive catalysis."

What began as curious observations of unexpected surface patterns has blossomed into a rich field that challenges fundamental assumptions in catalysis. As experimental and computational tools continue to improve, our ability to understand and harness surface reconstruction will undoubtedly grow. This knowledge promises to transform how we design and operate catalytic systems across numerous industrial and environmental applications.

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025